Variable Frequency Drive

Variable frequency drives (VFDs) are used in electro-mechanical drive systems to control motor speed. VFDs are essentially “motor controllers” and, as such, give the operator much greater control and flexibility over a traditional motor starter setup.

Compressor Applications

A VFD, used in conjunction with a programmable logic controller or process gauge on your compressor, can automatically vary the compressor speed to match your production. This enables the producer to fine-tune production by taking advantage of automatic speed control based on desired pressures or volumes. Need a VFD for your existing unit? We can retrofit your compressor with the latest technology, regardless of the manufacturer.

Pump Jack Applications

Variable frequency drives can also be used on your pump jack to set specific strokes per minute. You can finally smooth out your production without changing sheave sizes and timer settings, saving both time and money.

Economic advantages

Let our technology put an end to costly and time-consuming sheave replacement in the never-ending search for the perfect RPM. Smooth, consistent oil and natural gas production is at your fingertips! Combine this with up to a 30% reduction in your electric bill by efficiently managing speed and torque and the answer becomes clear. A VFD will eventually pay for itself!

We Do That!

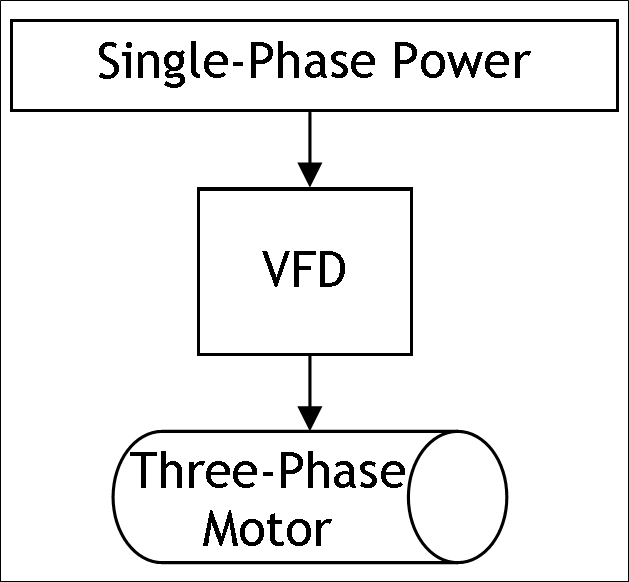

Do you have a higher-horsepower application, but only have

single-phase power available? Do you desire better control over your

production? Are you looking to maintain control over equipment and

energy costs? Rely on a Coulson Compression installed VFD solution.

We do that!